PROCESSING

Technologies That Improve Precision and Efficiency

One research goal at Asano is developing new processing technologies that boost production efficiency while reducing costs. Asano is working with university research organizations on several joint-development projects. Using advanced computer systems, we’re working to develop new processing technologies that will raise the benchmark of production-line precision and efficiency.

【New Processing Methods】

Asano is developing a variety of hard-finishing methods for heat-treated materials. By combining the Asano-developed simulation analysis system with state-of-the- art processing technologies, we’re finding new ways to improve efficiency. The processing methods now being developed in our laboratories will respond to needs for downsized equipment with quieter operation.

Topological Tooth Surface Finish

Topological Tooth Surface FinishState-of-the-art tooth surface finishing for ultra-high-performance gears

Recent years have brought a growing demand for equipment offering both smaller size and quieter operation. In response, Asano has developed the ultrahigh-precision Topological Tooth Surface Finish. Based on an extremely accurate simulation system, this innovative method provides superior surface processing of gear teeth having a complicated shape; it allows production of gears that achieve an unprecedented level of performance.

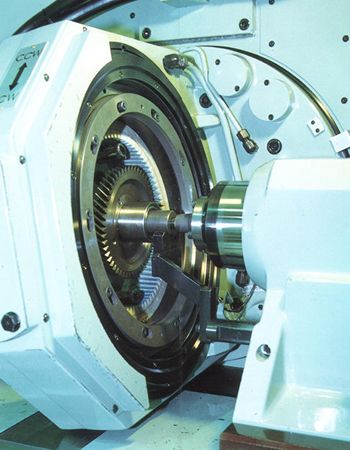

High-efficiency processing technology paired with unique control

Hard gear honing is a new, time-saving processing method for correcting tooth shape deviation in heat-treated gears. At Asano, we reduce costs by designing and manufacturing our own honing machines for teeth with a complicated shape. We also applied extensive processing know-how to develop a control system for the process. This hard gear honing technology corrects of tooth surface deviations five to ten times more efficiently than previous methods.

Hard Gear Honing

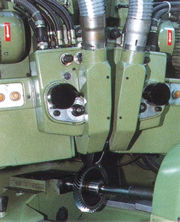

Hard Gear Honing Form Grinding

Form GrindingNew hard-finishing method

In the past, high-precision processing was a costly undertaking. Asano used a distortion correction method to develop an innovative low-cost process for heat-treated gears. Called Form Grinding, the process is based on three-dimensional simulation that allows easy correction of gear tooth shape. It also substantially shortens processing time regardless of production volume.